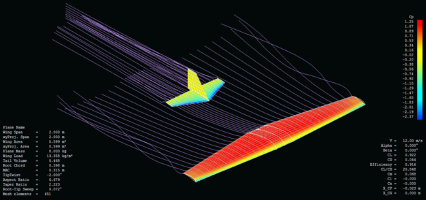

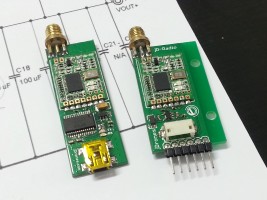

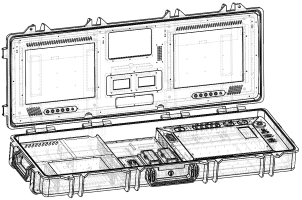

jDrones has engineering capabilities covering all the necessary areas for designing, creating and testing complete UAV systems. We also provide engineering services for UAV systems developers, manufacturers and existing operators who wish to create completely new systems, upgrade and add capabilities to existing systems, or maintain and repair any aspect of an existing system. We have the necessary know-how no matter whether we are talking about a fixed wing, multicopter, electric, or internal combustion engine powered drones.

If you or your company have any questions, custom needs. Please do contact us via contact us form

jDrones has in-house all the necessary capabilities from designing a drone from scratch to manufacturing the drones in small series. When large scale manufacturing is needed we use our certified partners. Our in-house capabilities include: